What The Ukraine War Revealed About American Industry

“For the want of a nail the shoe was lost,

For the want of a shoe the horse was lost,

For the want of a horse the rider was lost,

For the want of a rider the battle was lost,

For the want of a battle the kingdom was lost,

And all for the want of a horseshoe-nail.”

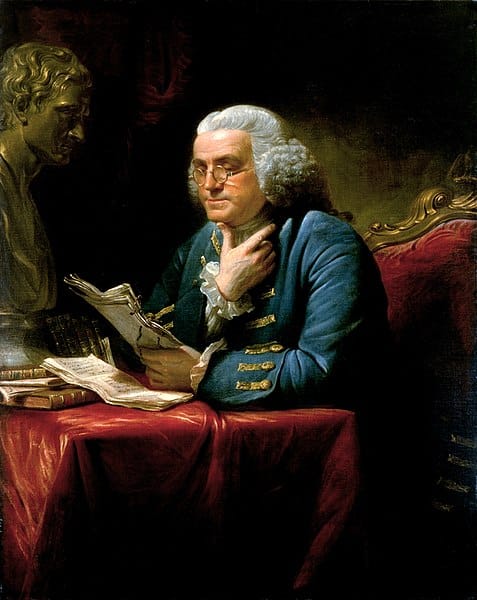

― Benjamin Franklin